Whenever any industry requires precision and efficiency in mixing, static mixers are preferred. These mixers have drastically changed the mixing game across all industries, particularly those involving the mixing of liquids, gases, and slurries.

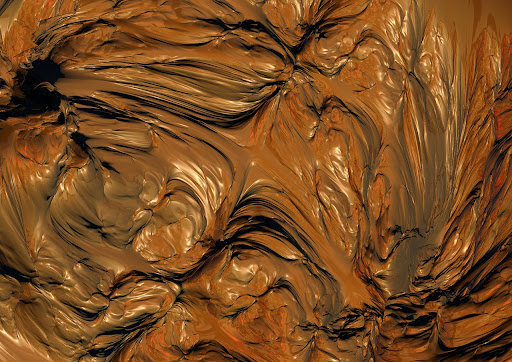

Paint industries widely use the mixing of thick liquids and only thorough mixing can create the perfect paint texture and required color. Paint industries can particularly benefit from industrial static mixer pipe fitting. Here are the top benefits of using a static mixer in paint manufacturing industries.

1. Efficient Mixing

Static mixers, also called motion-less or inline mixers utilize a unique design to provide effective and efficient mixing without any external help. When your paint industry is utilizing these static mixers, you will not have to invest in external energy sources like pumps or agitators.

Specialized mixing elements in static mixers such as vanes, baffles, and spiral-shaped components create the desired turbulence in the thick paint that allows efficient mixing of paint and the colors added in the buckets. These mixers can create a perfectly homogenized paint bucket that can not be created otherwise.

2. Improved Process Performance

By using static mixers in your paint industry, you can improve the performance of the manufacturing process. Since the mixer allows uniform blending, you can get a perfectly homogenized liquid that has consistent properties. If you have to create a paint with special characteristics, static mixers can promote chemical reactions among the ingredients that can make work faster and easier.

If you wish to transfer heat in the components, you can easily do so using the static mixers. You can easily customize the mixture using static mixers.

3. Allows Customization

Static mixers offer great versatility and customization options that may suit the needs and requirements of every customer. Since you can get mixers in any shape, size, and composition, you can easily customize the texture and color blending of your paints.

You can get tailored solutions to your mixing needs by using these static mixers. This type of versatility and customization is not offered by other mixers, whether traditional or modern.

4. Low Maintenance And Cost Efficiency

When you compare static mixers with traditional mixers, you will realize how cost-effective and low-maintenance solutions these mixers are for your paint manufacturing industry. Static mixers provide everything within one piece of equipment. When you get static mixers, you do not have to invest in separate parts or complementary equipment such as agitators or external energy sources.

You can easily save yourself some costs by investing in static mixers. These mixers are particularly low maintenance, you will not have to look for spare parts every other day. This further saves you from extra expenses.

Bottom Line

When you are running a paint manufacturing industry, investing in static mixers can make your work a lot easier. These mixers provide efficient mixing, cost efficiency, and customization of processes. These all-in-one pieces of equipment can help your paint industry perform the work much better than any other traditional mixers.